Categories

Contact Us

E-mail:

info@haxian.com

Tel:

+86-10-68631142 / 68631862

Address:

No. 8, Jinfu Road, Economic Development Zone, Daxing District, Beijing

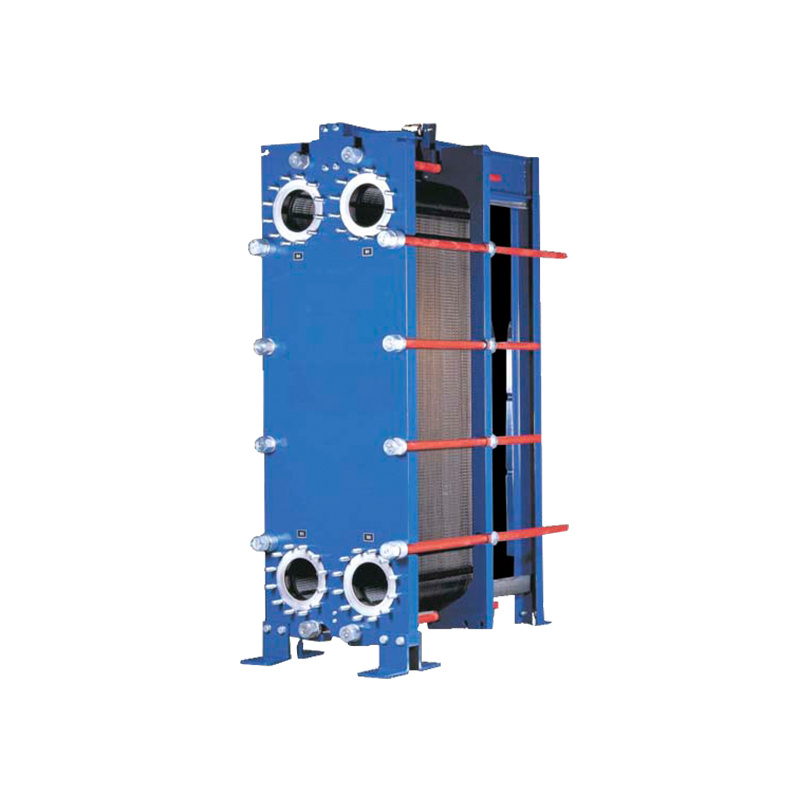

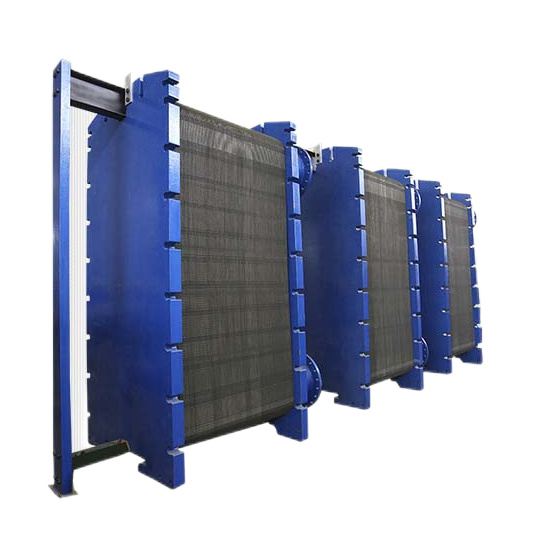

Plate heat exchanger

Key words:

- Description

-

High heat transfer efficiency

The Heat transfer coefficient K of plate heat exchanger is in the range of 3000-6000W/m2. oC.act according to circumstances

The heat exchange plate is easy to disassemble, and suitable heat transfer effect and capacity can be obtained by adjusting the number of heat exchanger plates or changing the pass.Low heat loss

Due to its compact structure and small size, the surface area of the heat exchanger is also very small, resulting in minimal heat loss. Usually, equipment does not require insulation.Reliable use

Two seals have been designed on the sealing device between the plates, along with signal holes. Once a leak occurs, it can be discharged from the outside of the heat exchanger, preventing the mixing of the two medium and serving as a safety alarm.It is conducive to the utilization of low temperature heat source

Due to the almost complete countercurrent flow of the two medium and their high heat transfer efficiency, using them to recycle low-temperature waste heat or utilize low-temperature heat sources is an ideal equipment.Small footprint, easy to maintain

The structure of plate heat exchangers is extremely compact, occupying only 1/2-1/3 of the space of shell&tube heat exchangers under equal heat conditions.Less Friction loss

On the premise of the same heat transfer, compared with the shell&tube heat exchanger, the plate heat exchanger has reduced the equipment investment, infrastructure investment, power consumption and other costs due to the reduction of heat exchange area, floor area, fluid resistance, cooling water consumption and other project values. Especially when expensive materials are needed, the equipment is more economical due to the efficiency and thin plates.Installation Dimension Table for Technical Parameters of Plate Heat Exchanger Specification

No of Plates

Basic dimensions(mm) Max Processing

Flow (㎥/h)

Weight (Kg)

L

W

H

Lower Ports Distance(H)

Centre-to-centre

Spacing between

Upper Ports (B2)

Centre-to-centre

Spacing between

Upper Port and

Lower Port (H2)

Port Pipe

Diameter (DM)

Operating

Pressure (Mpa)

AT25A 13 159 190 430 46.5 73 337 25 0.6 10 15 21 210 16 25 237 16.8 31 264 17.6 37 300 18.5 45 336 19.5 51 363 20.3 AL40A 9 400 340 605 150 140 390 40 1.0 27 80 17 400 84 25 400 89 33 550 93 43 550 98 51 550 102 59 750 107 67 750 111 75 750 116 83 850 120 93 850 125 101 850 130 AL40B 17 620 320 901 140 140 655 50 1.0 42 113 33 620 128 51 620 142 67 900 155 83 900 169 101 900 184 117 1150 197 133 1150 212 151 1150 226 167 1450 239 183 1450 253 201 1450 268 AL65A 27 700 380 1005 200 188 690 65 1.6 72 190 41 620 206 55 620 220 69 950 236 81 900 252 95 900 266 109 1200 380 1005 200 188 690 65 1.6 72 282 123 1150 296 137 1150 312 151 1400 328 165 450 342 177 1450 358 AL100A 23 600 517 1027 255 239 612 100 1.6 170 380 33 600 395 45 600 409 55 800 425 67 800 439 77 800 453 89 960 469 101 960 485 111 960 500 123 1150 515 133 1150 530 145 1150 545 AL1008 41 800 517 1276 255 239 836.4 100 1.6 170 403 45 800 415 57 800 558 63 900 570 75 900 608 81 900 620 91 1000 638 97 1000 650 109 1000 678 115 1200 690 135 1200 750 151 1200 800 AL150A 19 1012 620 1245 275 298 706 150 1.6 380 558 25 1012 570 33 1122 598 37 1122 610 45 1222 648 49 1222 660 57 1322 698 63 1322 710 69 1322 751 75 1522 763 87 1722 795 99 1722 825 AL150B 37 850 620 1545 275 298 1006 150 1.6 380 726 57 850 778 75 850 825 95 1200 875 113 1200 924 131 1200 973 151 1500 1020 169 1500 1070 189 1500 1118 207 1800 1168 227 1800 1218 245 1800 1268 AL150C 59 900 620 1845 270 298 1306 150 1.6 380 876 73 900 928 89 900 975 103 1200 1025 117 1200 1074 133 1200 1125 147 1500 1170 161 1500 1220 177 1500 1268 191 1800 1318 205 1800 1368 221 180 1418 AL200A 79 1050 726 1752 320 340 1176 200 1.6 680 1340 93 1050 1400 105 1050 1460 119 1400 1520 131 1400 1580 145 1400 1640 157 1500 1700 171 1500 1760 AT200B 237 1800 725 809.5 315 344 1507 200 1.6 680 1968 263 1800 2068 AT2000 63 950 725 2109.5 400 344 1492 200 1.6 680 1530 85 950 1625 105 950 1717 127 1350 1810 147 1350 1905 169 1350 1998 189 1800 2091 211 1800 2185 231 1800 2277 243 2000 2327 253 2000 2371 263 2000 2420 AT250A 73 950 927 2149 400 439 1655 250 1.6 1060 2272 91 950 2364 109 950 2455 127 1250 2547 145 1250 2640 163 1250 2731 181 1600 2823 201 1600 2920 219 1600 3011 237 1800 3103 245 1800 3150 255 1800 3195 AT250B 71 950 9277 2449 400 439 1655 250 1.6 1060 2626 85 950 2716 101 950 2800 115 1250 2885 129 1250 2971 143 1250 3057 157 1600 3142 171 1600 3228 185 1600 3315 201 1800 3400 215 1800 9277 2449 400 439 1655 250 1.6 1060 3485 229 1800 3571 AT250C 83 1250 927 2749 400 439 1955 250 1.6 1060 3076 101 1250 3200 117 1250 3323 135 1250 3447 153 1600 3570 171 1600 3695 189 1600 3817 205 1600 3941 223 2000 4065 241 2000 4188 259 2000 4311 277 2000 4435 AL300A 75 1250 1174 2393 470 596 1454 300 1.6 1530 4171 97 1250 4334 119 1250 4497 141 1250 4661 163 1800 4824 183 1800 4987 205 1800 5150 227 1800 5134 259 2200 5558 271 2200 5640 281 2200 5722 291 2200 5800 AL300B 69 1250 1174 2799 470 596 1860 300 1.6 1530 4946 87 1250 5108 105 1250 5270 121 1250 5432 139 1600 5593 157 1600 5755 173 1600 5917 191 1600 6080 209 2200 6240 227 2200 6400 243 2200 6564 261 2200 6726

Key words:

Get A Quote

We will contact you within one working day. Please pay attention to your email.

News

We Help Customers To Meet The Great Challenges Of Our Time